Advanced Manufacturing

0

㎡

Factory Area

0

Production Lines

0

Units

Monthly Output

0

+

Skilled Worker

Reliable Standing Desk Frame Factory

Our 26,640㎡ automated factory utilizes cutting-edge technology and adheres to ISO 9001 standards, ensuring our standing desk frames consistently meet the highest global performance and reliability standards.

Full-Scale Manufacturing Infrastructure

With advanced production equipment across every stage, our factory is designed for large-scale manufacturing, ensuring efficient, high-precision production of top-quality desk frames. We continuously invest in enhancing our capabilities to meet growing market demands.

10-Step Standing Desk Manufacturing Process

1

2

3

4

5

6

7

8

9

10

Material Preperation

We source only the finest materials, including top-grade metal sheets, motors, control systems, and transmission components, to ensure every desk frame we produce is durable, reliable, and built to last.

Laser Cutting Manufacturing

Using top-tier laser cutting machines, we achieve tolerances as tight as ±0.1mm. The result: clean, burr-free edges, reduced need for secondary processing, and faster, more efficient production.

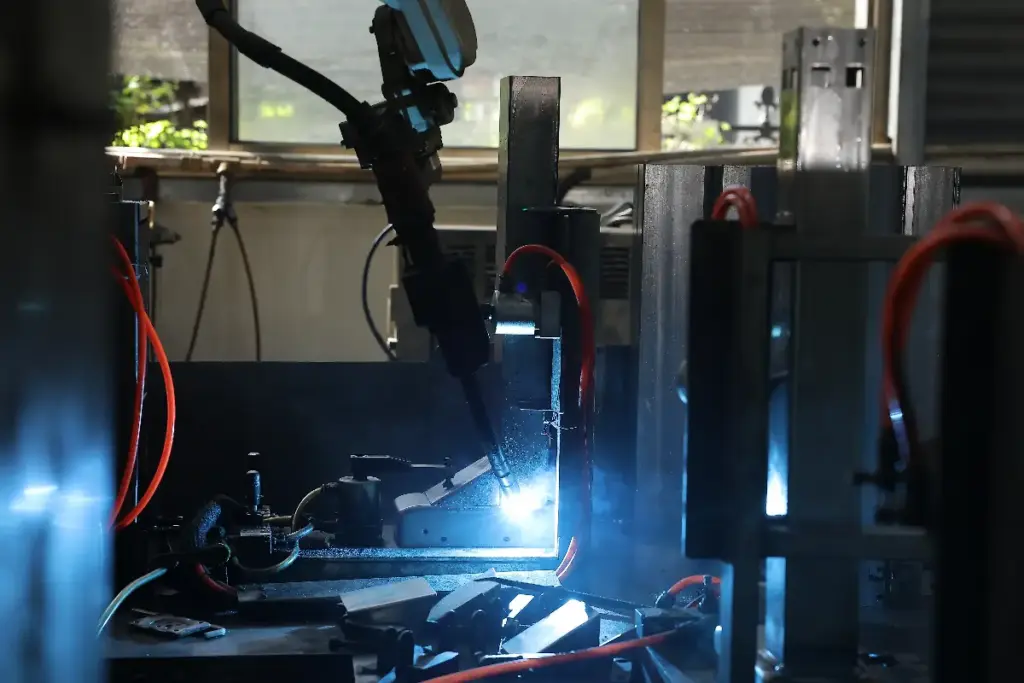

Welding & Bending

We combine robotic laser welding for standard parts with skilled manual welding for complex custom jobs, ensuring strong, reliable welds free from defects.

Bending is performed with CNC precision, maintaining accurate dimensions for complex shapes.

Polish

All components are hand polished where needed, removing welding spots and defects. This attention to detail ensures smooth surfaces, enhanced coating adhesion, and enhanced product aesthetics.

Powder Coating

We use eco-friendly powder coats which are compliant to REACH and ROHS. The coating is electrostatically coated and cured in curing ovens, creating a durable, scratch-resistant, corrosion-proof finish with a uniform appearance.

Assembly

Each unit is meticulously assembled by our technicians following strict SOPs, with thorough checks for stability, smooth lifting, and noise-free operation, ensuring the final product performs perfectly.

Quality Inspection

We perform checks at each step, including checking such components as columns, controllers, and wiring, and ensuring their accuracy, functionality, and appearance. Any problems result in 100% re-inspections, ensuring high quality during production.

Fatigue Test

Desk frames undergo fatigue testing, simulating years of use by applying weight and continuous movement, verifying their stability and long-term durability under real-world conditions.

Packing

We use 5-layer corrugated cartons with EPE foam or honeycomb paper, tested to withstand up to 300kg stacking pressure.

Loading

Protective measures are built into goods, such as reinforced pallets and careful stacking, minimizing logistics risks and allowing safe and reliable delivery.

Material Preperation

We source only the finest materials, including top-grade metal sheets, motors, control systems, and transmission components, to ensure every desk frame we produce is durable, reliable, and built to last.

Laser Cutting Manufacturing

Using top-tier laser cutting machines, we achieve tolerances as tight as ±0.1mm. The result: clean, burr-free edges, reduced need for secondary processing, and faster, more efficient production.

Welding & Bending

We combine robotic laser welding for standard parts with skilled manual welding for complex custom jobs, ensuring strong, reliable welds free from defects.

Bending is performed with CNC precision, maintaining accurate dimensions for complex shapes.

Polish

All components are hand polished where needed, removing welding spots and defects. This attention to detail ensures smooth surfaces, enhanced coating adhesion, and enhanced product aesthetics.

Powder Coating

We use eco-friendly powder coats which are compliant to REACH and ROHS. The coating is electrostatically coated and cured in curing ovens, creating a durable, scratch-resistant, corrosion-proof finish with a uniform appearance.

Assembly

Each unit is meticulously assembled by our technicians following strict SOPs, with thorough checks for stability, smooth lifting, and noise-free operation, ensuring the final product performs perfectly.

Quality Inspection

We perform checks at each step, including checking such components as columns, controllers, and wiring, and ensuring their accuracy, functionality, and appearance. Any problems result in 100% re-inspections, ensuring high quality during production.

Fatigue Test

Desk frames undergo fatigue testing, simulating years of use by applying weight and continuous movement, verifying their stability and long-term durability under real-world conditions.

Packing

We use 5-layer corrugated cartons with EPE foam or honeycomb paper, tested to withstand up to 300kg stacking pressure.

Loading

Protective measures are built into goods, such as reinforced pallets and careful stacking, minimizing logistics risks and allowing safe and reliable delivery.

How Our Production Capacity Benefits You

Fast Delivery

Our optimized production workflow and strategic scheduling deliver your orders punctually within 15-25 days, empowering you to advance projects without delays.

Consistent Quality

Backed by ISO 9001 certification and strict quality control, each product is guaranteed to meet CE, ROHS, and international standards, ensuring consistent quality delivery.

Cost Efficiency

Our highly scalable production and lean operations significantly lower overall costs, thereby allowing us to deliver competitive rates and outstanding value.